Kanban vs. Gantt chart: what to choose for your project

You surely already heard of the Kanban boards and Gantt charts. But have you ever wondered what ...

Gravia, a well-known construction company with years of experience managing complex projects, faced ongoing challenges in tracking equipment and coordinating between field teams and the office.

Equipment was constantly moving between construction sites, warehouses, and offices, and without a centralised tracking system it was difficult to avoid delays, losses, and unnecessary costs.

Their goal: to implement a solution that would give everyone – from office staff to field workers – instant, accurate visibility of equipment status, accessible directly from a mobile phone.

Before introducing Gauss Box Equipment, the tracking process relied on:

Manual records

Emails

Phone calls

This led to:

No real-time insight into tool availability

Inaccurate inventory estimates

Duplicate purchases and extra costs

Long delays waiting for confirmations from the office

The result: The admin team spent too much time chasing updates, while field workers were left waiting for approval before they could continue work.

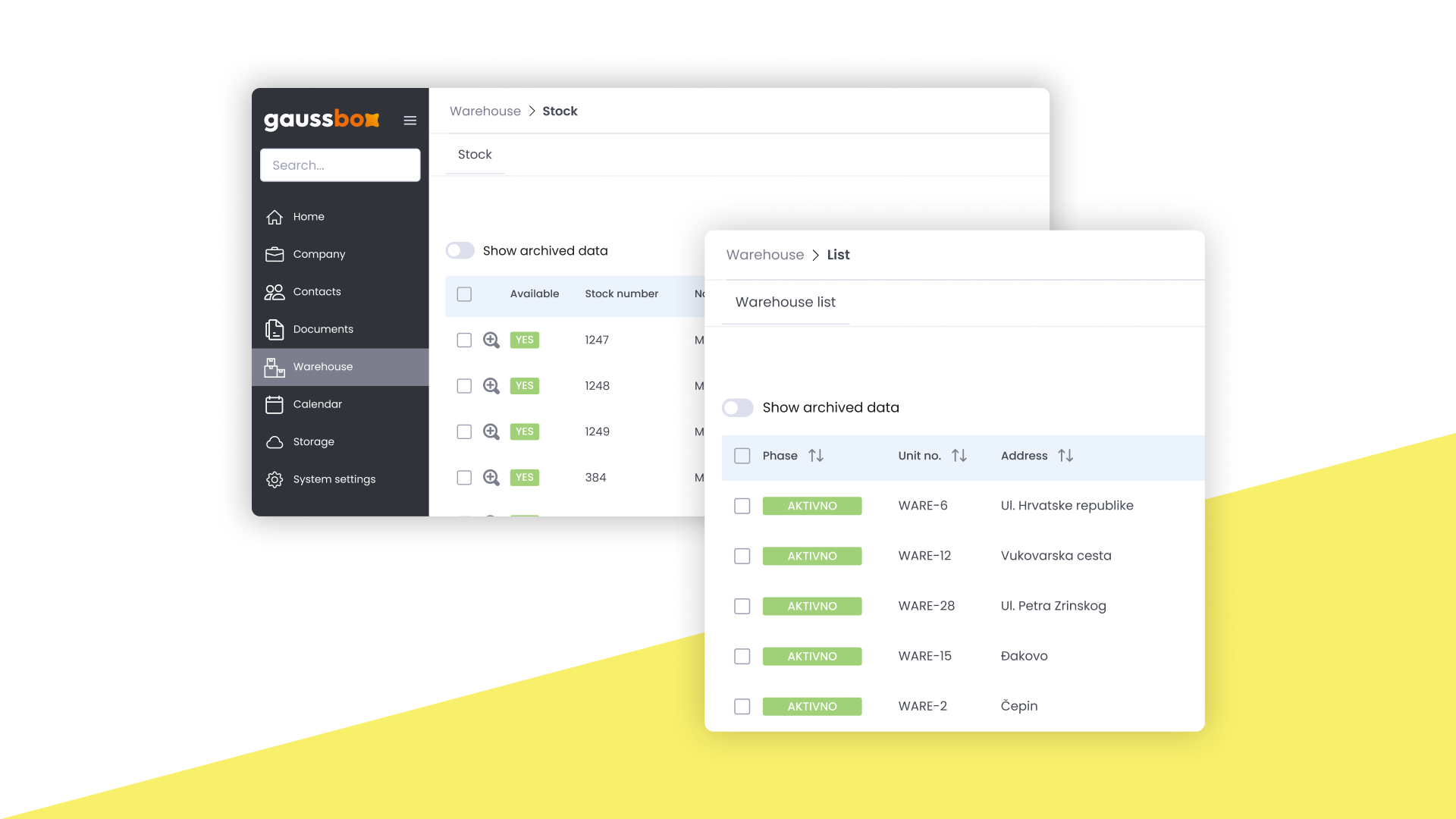

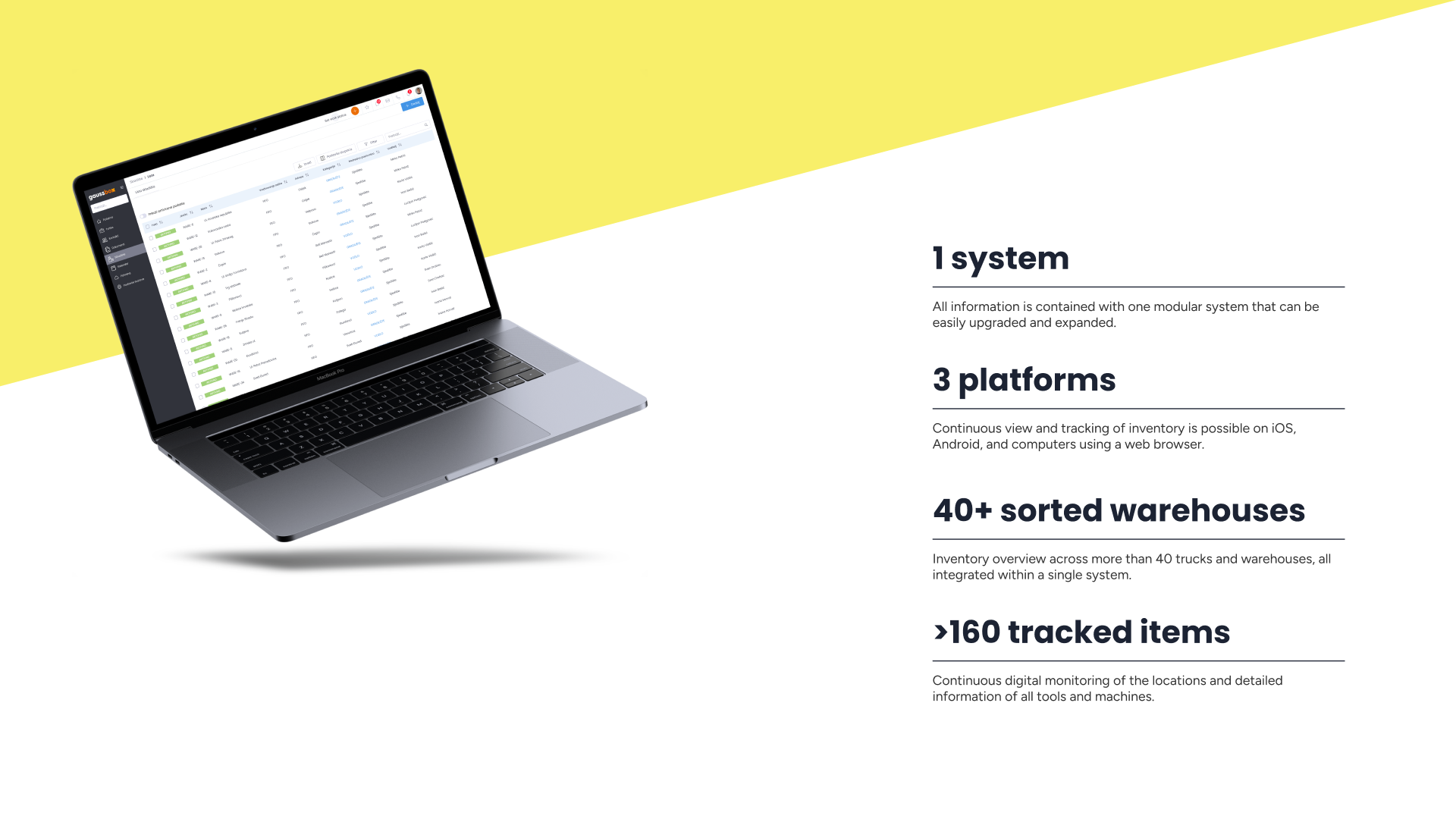

Gauss Box Equipment enables end-to-end equipment management – from scanning to usage – all in one place, fast and easy.

Key features:

Unique QR code tags for every piece of equipment

Mobile scanning to log check-outs and returns

Automatic recording of location, user, and status

Real-time data available to the entire team

Implementation process (under 1 month):

Process analysis

System configuration & integration

Staff training

The system was fully operational from day one.

Three months after implementation:

30% less time spent on inventory administration

90% increase in operational efficiency

2,000+ equipment records archived and ready for analysis

Outdated data eliminated

Costs reduced by avoiding duplicate purchases

Key advantage: Gravia now has a scalable, locally supported solution tailored to their needs – no need to juggle multiple separate tools.

This project shows how digitising a critical process can dramatically improve productivity – even in industries where physical equipment is at the core of operations.

With Gauss Box Equipment, Gravia has:

Accelerated information flow

Reduced administrative workload

Increased control over resources

Stay up to date with the latest industry insights with notifications delivered straight to your inbox.